Tag: avr

-

scanlime040 – Test Jig Quick Look

I found these two test jigs for sale at a local business that was relocating. They would have been used as part of the quality assurance procedure for smart bike lights. Later we might go into more detail on the firmware, or repurpose the formidable hunks of metal for another project! Thank you so much…

-

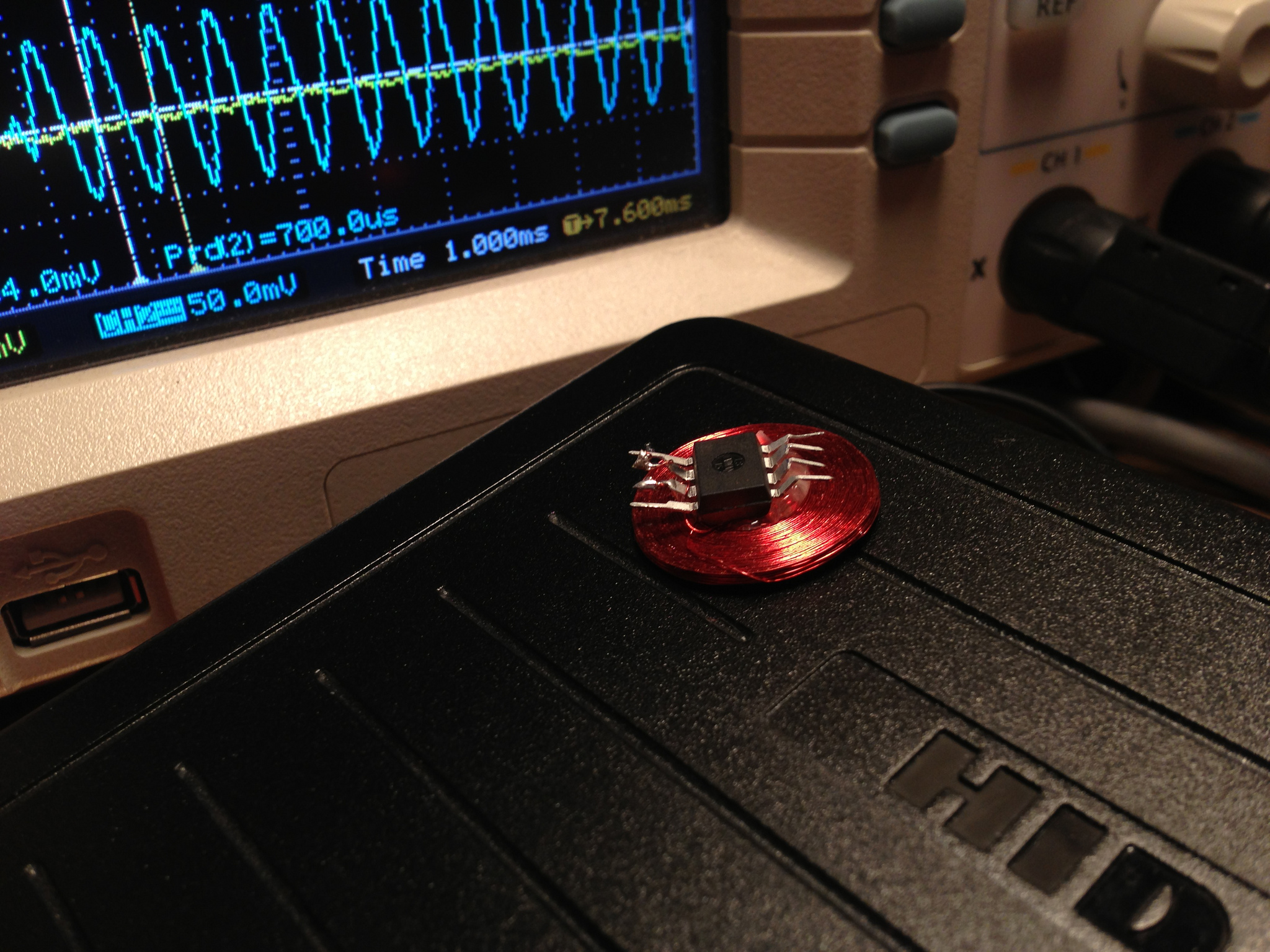

AVR RFID, Optimized and Ported to C

Way back in 2008, I posted a writeup about using an AVR microcontroller as an RFID tag. Since then, it’s been great to see many people pick up this code and build their own DIY RFID tags. In my original project, I was just interested in using an AVR as a way of emulating any…

-

AVRFID 1.1 Firmware

I don’t normally write bloggy posts on every version of every source file I check in, but every so often an older project sees some more activity, and I love the opportunity to revisit software I wrote years ago. Sometimes I wonder why I wrote such-and-such thing that way and oh my god what an…

-

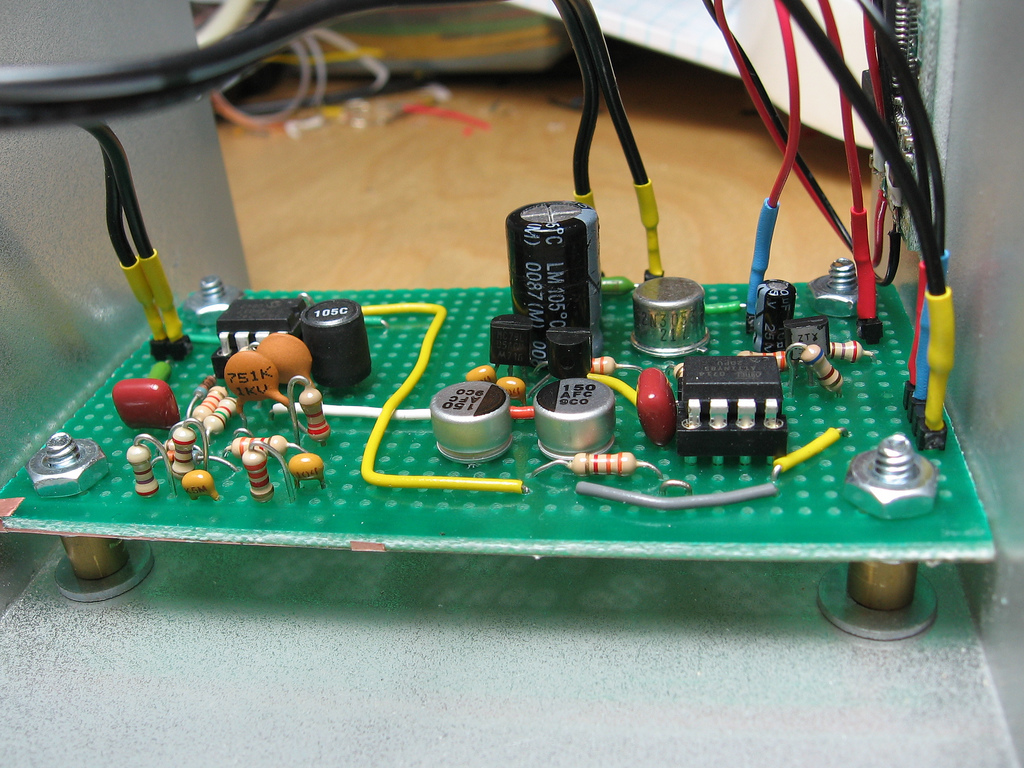

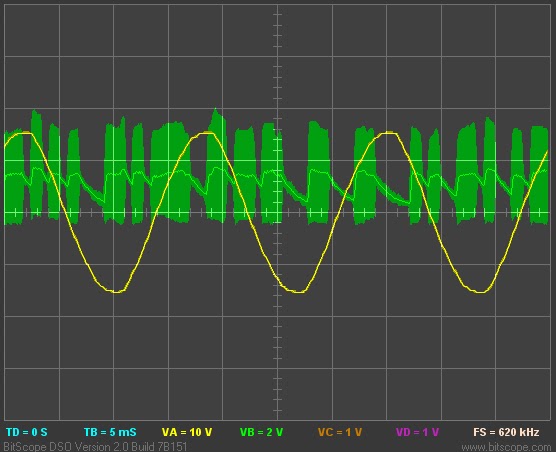

Open source extra-sensitive high resolution TED receiver

Previously on the bloggy blog, I posted a few of my projects related to home data acquisition and to The Energy Detective (TED), a whole-house power measurement device. I made a set of homebrew wireless temperature sensors that display graphs on a digital picture frame, I reverse engineered the TED protocol, built a small self-contained…

-

Lego Sky

Over the weekend, I had a chance to finish up a project that I started (and immediately became distracted from) several weeks ago. In our house, Paul and I have a game room. This is where the video games live, as well as other assorted geekery. We have Magic cards, D&D books, some manga.. it’s…

-

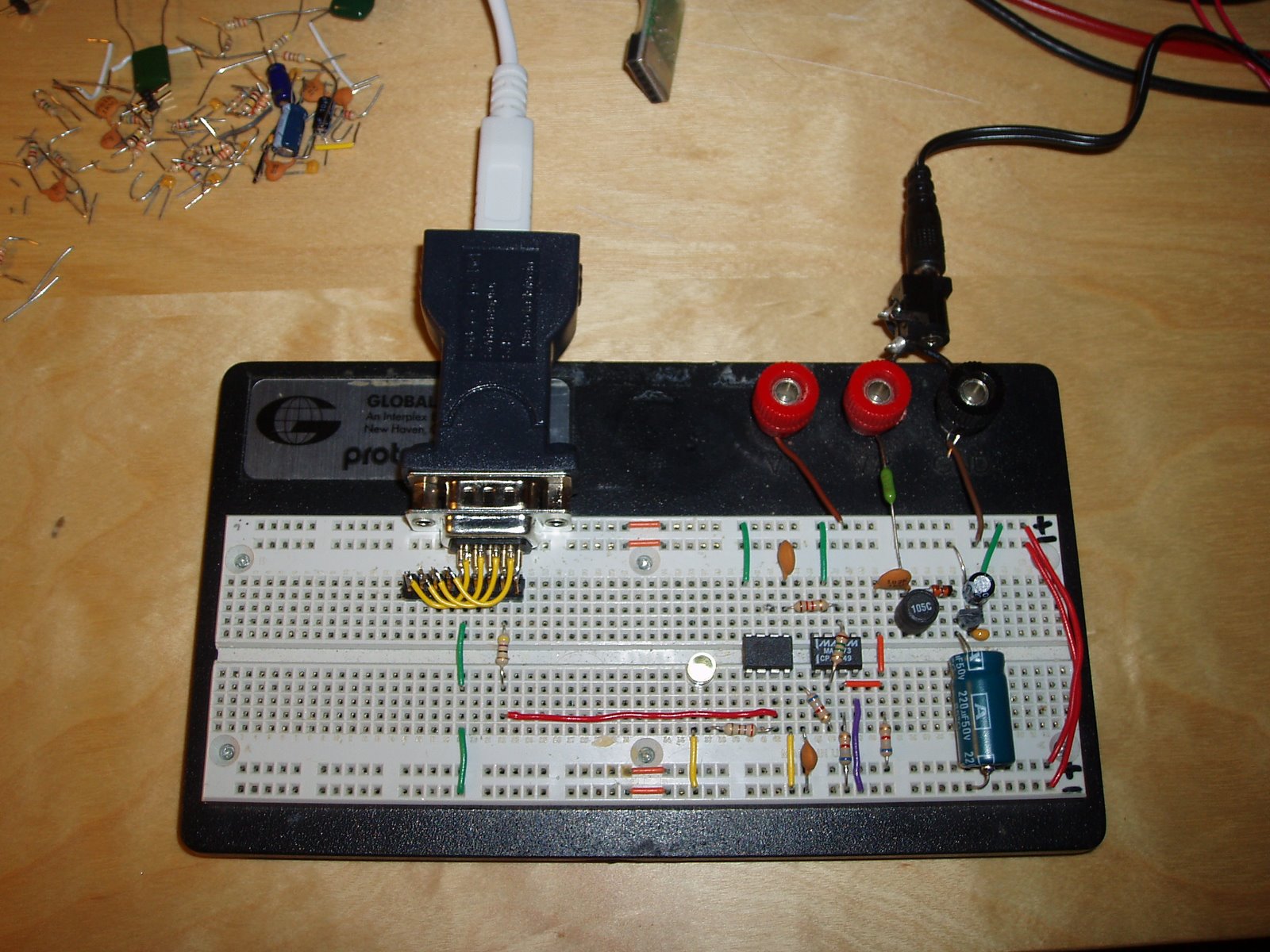

Self-contained TED receiver

My previous entry introduced a homebrew receiver for the powerline-based data protocol used by The Energy Detective. I just designed a second revision of that receiver. This one is self-contained: It gets power and modulated data from a 9V AC wall-wart transformer, and decoded data leaves via an RS-232 serial port at 9600 baud. Best…

-

Interfacing with The Energy Detective

I recently bought The Energy Detective (TED), a pretty inexpensive and friendly way to keep tabs on your whole house’s electricity usage. It’s a lot like having a more featureful version of your utility company’s power meter, sitting on your kitchen counter. It can estimate your utility bill, and tell you how much electricity and…

-

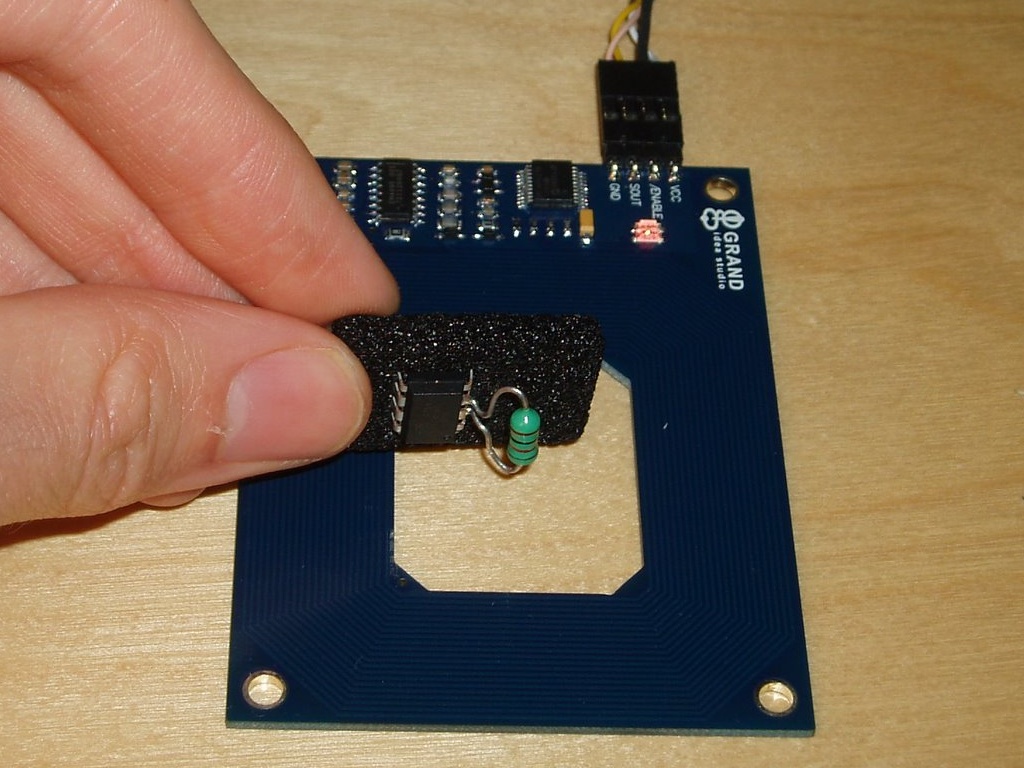

Using an AVR as an RFID tag

Experiments in RFID, continued… Last time, I posted an ultra-simple “from scratch” RFID reader, which uses no application-specific components: just a Propeller microcontroller and a few passive components. This time, I tried the opposite: building an RFID tag using no application-specific parts. Well, my solution is full of dirty tricks, but the results aren’t half…

-

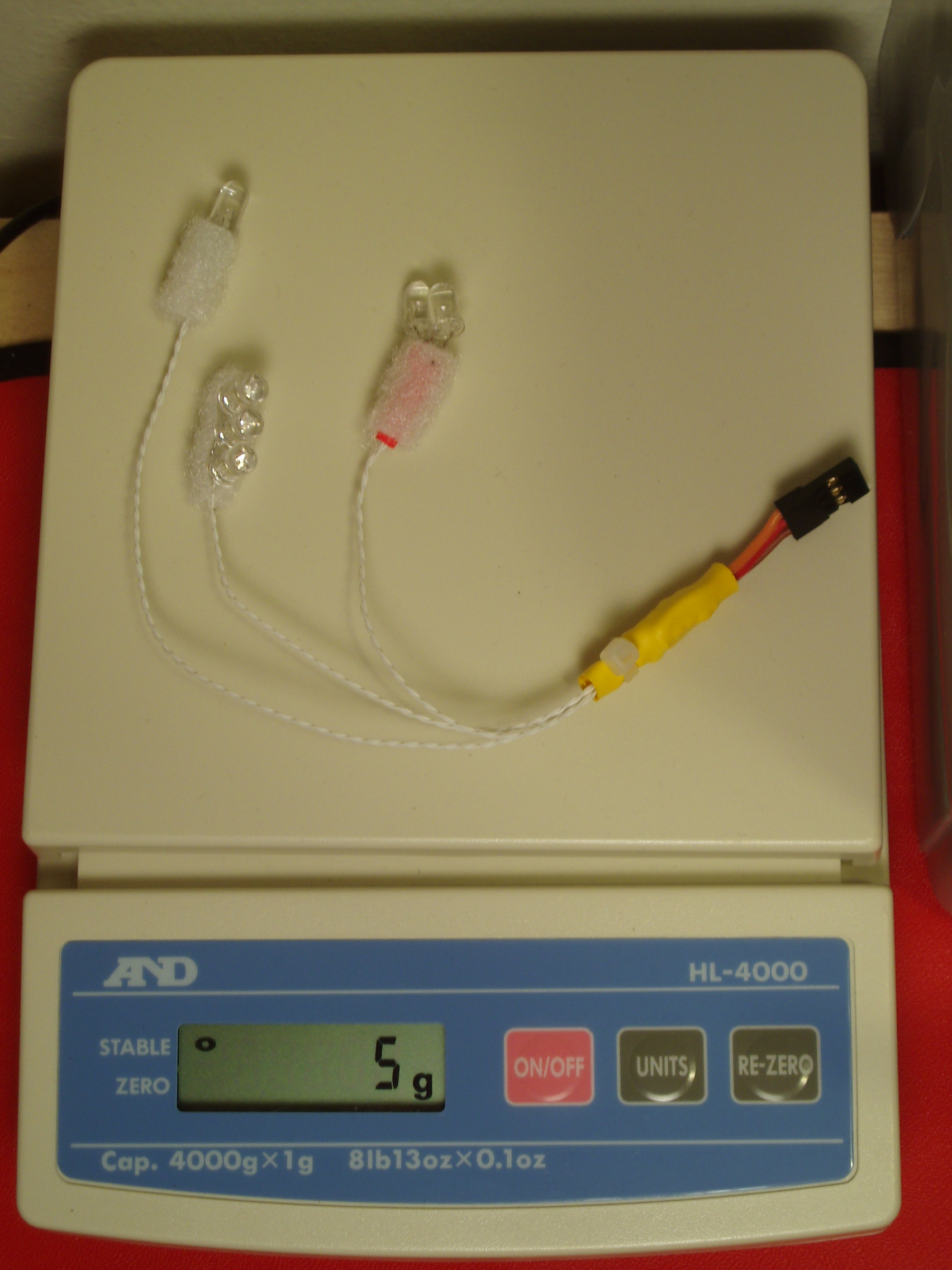

R/C helicopter lights, Revision A.5

Atmel is going to personally revoke my electrical engineering license if they ever find out what’s in that yellow heat-shrink blob, but I now have a shiny new 5 gram version of my helicopter light kit =D This version has all the same remote-control dimming and strobe capabilities of the heavier Revision A. The only…

-

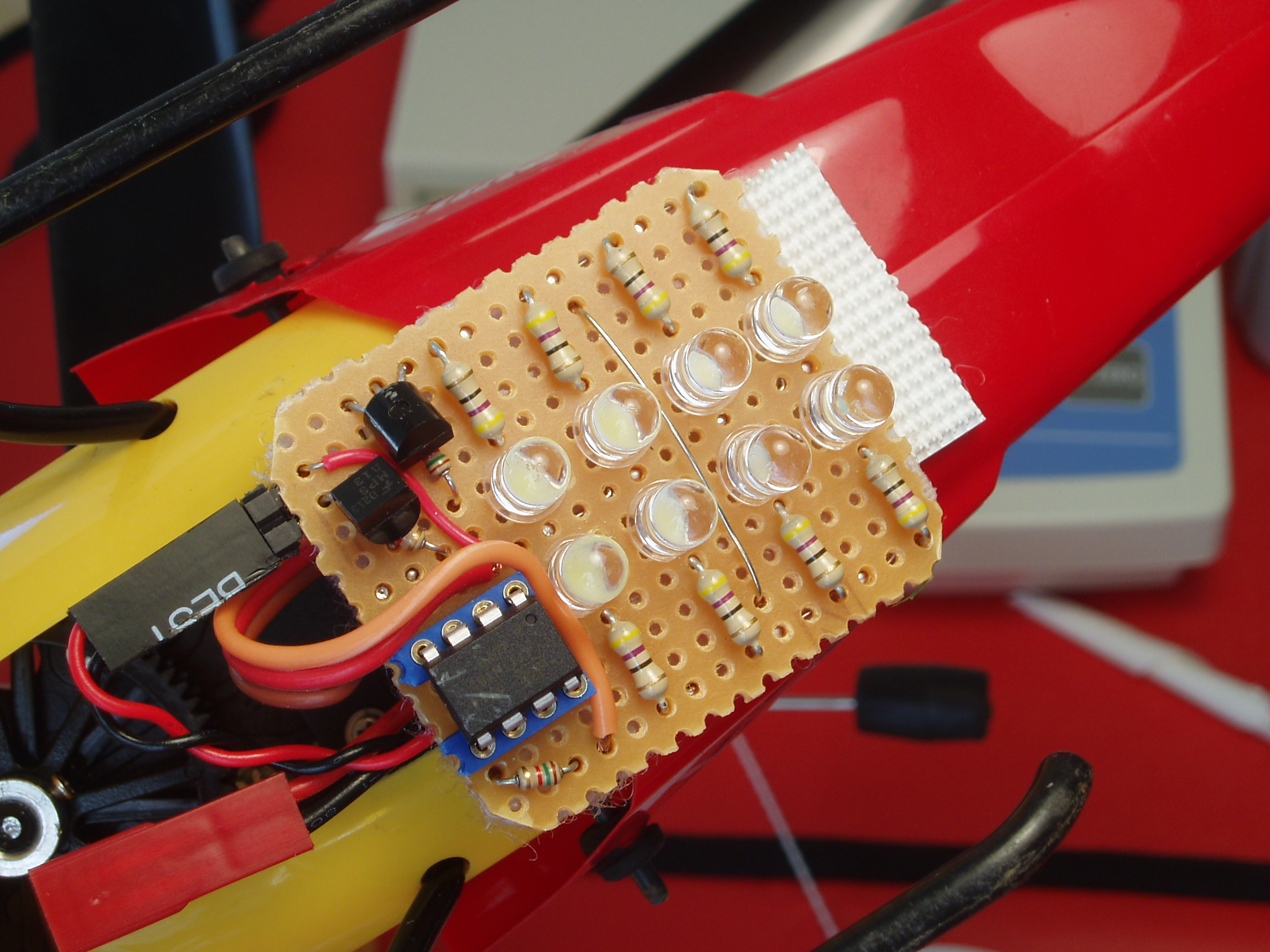

Hardware sketch: R/C helicopter light kit

As great as it is to finish a professional-looking hardware project with optimum component choices and full design documentation, I love the feeling of sketching in hardware (or as I’ve called it in the past, improvisational electrical engineering). Despite all the faults and rough edges in today’s development tools, we do live in a world…