Tag: Projects

-

The Ardent Mobile Cloud Platform

This year I had the pleasure of working on a big art project for Burning Man with a wonderfully talented group of artists and engineers in my community. It started with a simple idea: Let’s bring a variable reach forklift to Burning Man, and put a cloud on it.

-

How we built a Super Nintendo out of a wireless keyboard

This is a guest article I wrote for Adafruit, on the story of how we built the hardware behind the new Sifteo Cubes, our second generation of a gaming platform that’s all about tactile sensation and real, physical objects.

-

X-10 SmartRemote

I’m not even sure why I built this at all. I guess I did always have a childhood fascination with making things that seemed professional in some way. A simulacrum of some expensive piece of A/V equipment, or simple computer games that came in a shoe box with construction-paper cover art. This is another ancient…

-

Neon Scope

It’s so hard for me to clean up my office. I’ll see a random collection of objects that I’m supposed to be sorting, putting away, and/or throwing in the garbage.. and I can’t help playing with them instead. This time the objects in question were an old CCFL backlight inverter, a neon flicker-flame bulb, and…

-

Cube64 GameCube to N64 Adaptor

Enjoy retro N64 games, but can’t stand the controller? That’s the situation I found myself in about 7 years ago, back in 2004. So I built an adaptor, to use Game Cube controllers on the N64. (tl;dr… Cube64-DX on Google Code) The adaptor hardware is very simple- all you need is a PIC microcontroller. I…

-

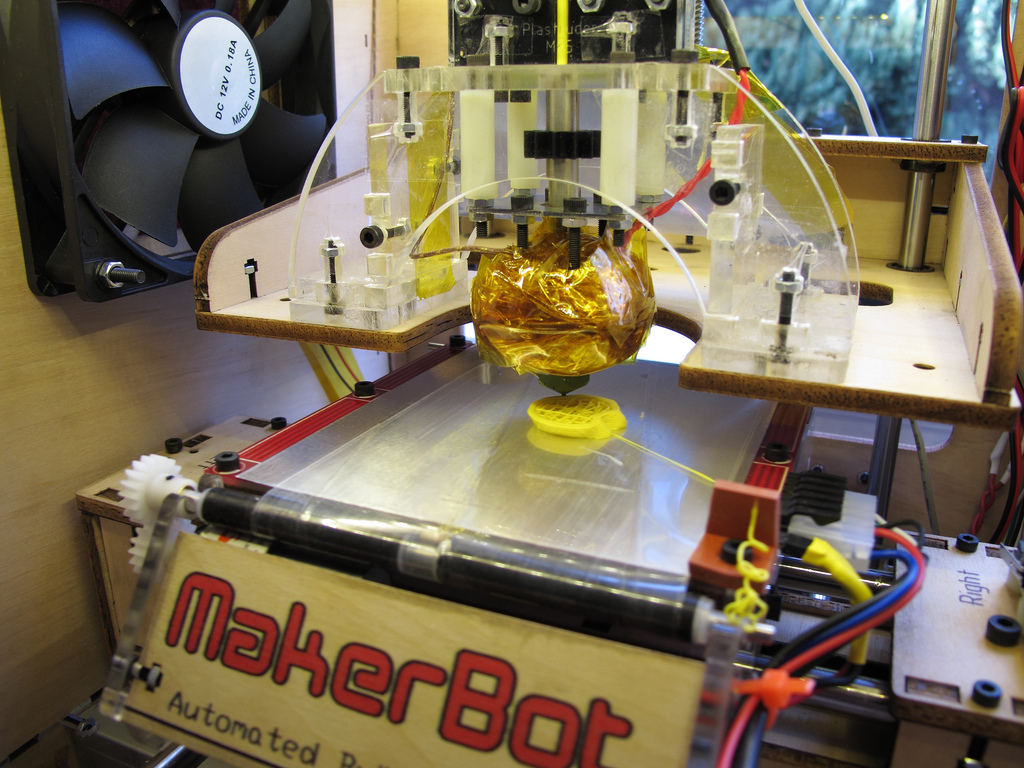

Getting to know the Thing-O-Matic

This post is mostly an apology for not having done anything blog-worthy in the past few months. As usual, life has been full of Things. Like Katamari Damacy. Kinda. On the technical side, I’ve had a few interesting ideas bouncing around in my head lately: 3D Printing. Seems like a space ripe for DIY innovation,…

-

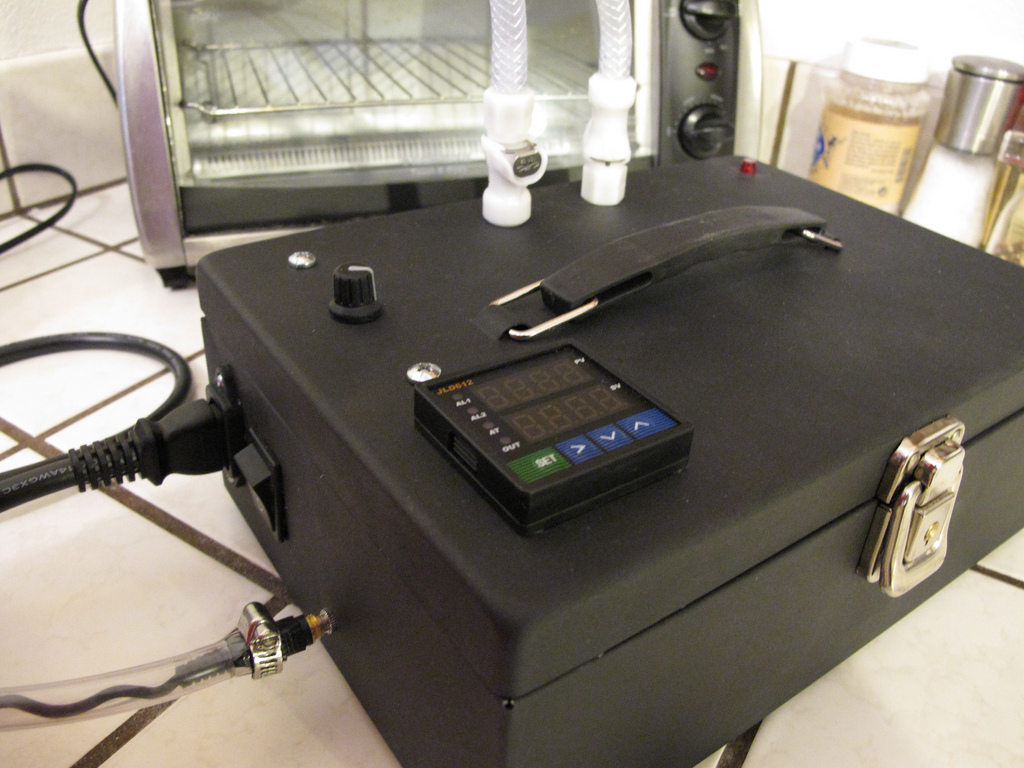

Espresso Machine Sous-vide

This project is a bit different from what I normally do. No firmware to write, just several trips to the hardware store and a lot of quality time with the drill, files, and nibbler. But this one has a higher purpose: Food. It was actually a commission by a friend of mine. He wanted to…

-

Hacking a Digital Bathroom Scale

People all around the internet have been doing cool things with the Wii peripherals lately, including the Wii Fit balance board. Things like controlling robots or playing World of Warcraft. But what if you just want one weight sensor, not four? The balance board starts to look kind of pricey, and who wants to deal…

-

“Luggable” power pack

Paul and I are leaving on a cross-country train trip next week, for Jen and Shawn’s wedding in Colorado. I’m sure the view will be great, and I’m bringing a handful of books- but Paul and I are geeks and we need our electro-doodads. If only we had a way to run our Nintendo DS…

-

Mmm, crispy.

I hate power electronics. This was my first attempt at fixing a broken Cuisinart cordless kettle. The original symptoms: I notice the kettle occasionally turns itself off. If I turn it back on, it works again for a little while. This kept up for a day or so, then it refused to turn on at…

-

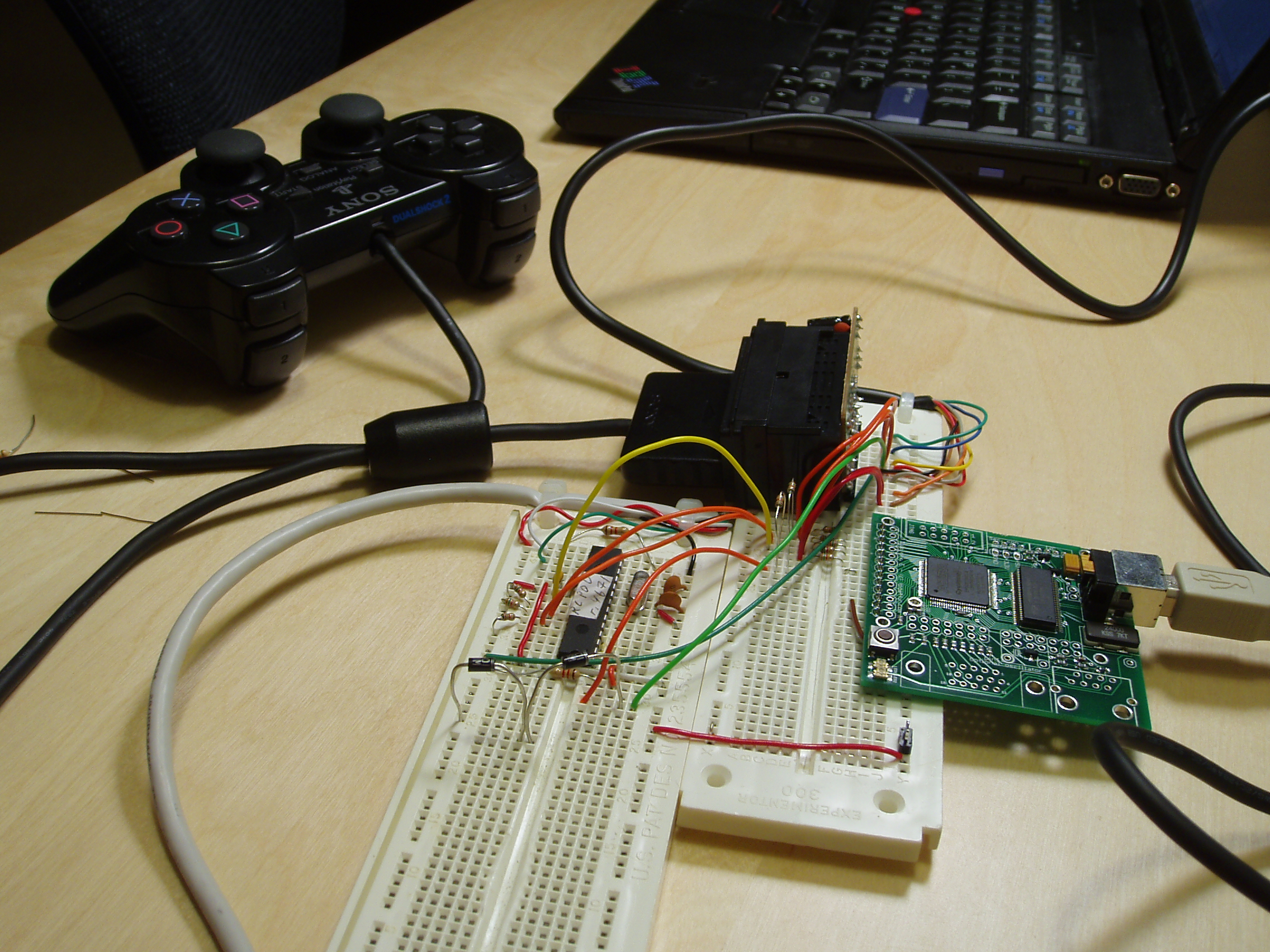

Hardware hackery and the Dual Shock protocol

The hardware-tinkering mood I’ve been in lately shows no sign of subsiding. The theme this time: Everything over cat5. Backing up a bit… It’s summer! Hooray. So, how does one make the most of the season without actually doing something crazy like going outdoors? Of course the answer is to play video games in a…

-

Mobile map inspiration

So, I’ve been itching to do something really cool with Python on Symbian Series 60. The first thought was a way to upload images directly from the phone to Gallery. Well, it still needs some polishing, but I wrote most of that at the last SVLUG hackfest. Right now it takes a picture with the…